A worn ball joint will pivot horizontally and vertically, negatively affecting low-speed operation and becoming especially dangerous at high speeds. Recognizing the knocking in the wheels when cornering, fixing old ball joints is an important part of keeping your vehicle safe on the road.

Part 1: Preparation

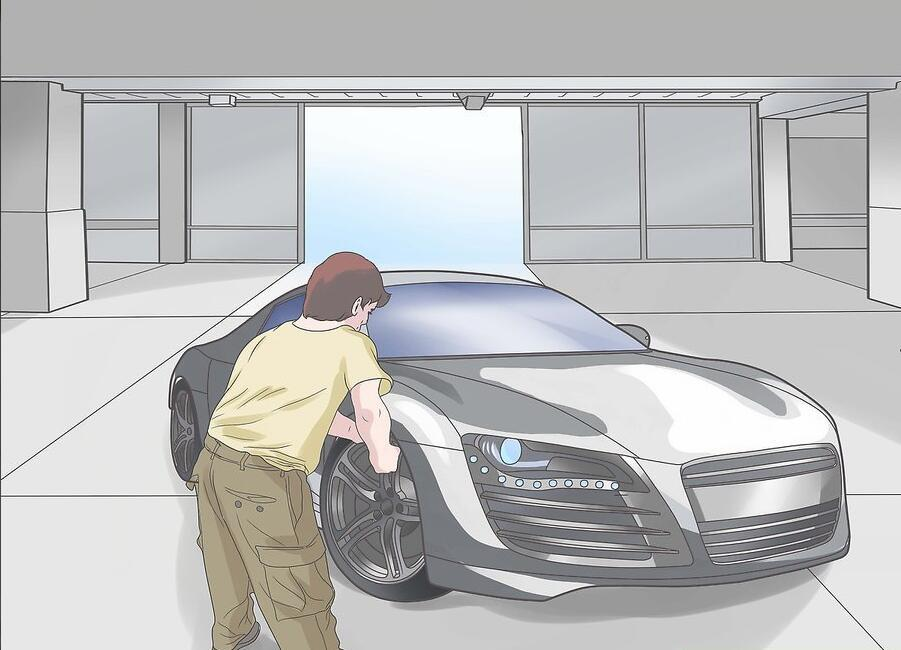

1. Park the vehicle: park on a flat ground and block the front and rear wheels. Make sure it doesn't move anywhere while you're working.

2. Check the ball joint to make sure it needs to be replaced. Find out if your vehicle has a braced suspension or a control arm, then check the wheel joints by lifting the control arm near the ball joint, check wheel clearance, or lift the car and use a pry bar to check with braced suspension wheel play.

There should be no gap between the ball joint and the point of contact. If you see any space, or the wheels move a lot, the joints need to be replaced.

3. Remove the wheel and access the ball joint. Depending on the steering assembly, the brakes may also need to be set aside.You can clearly see the control arm after removing the tire.

4. Spray the bolts with rust remover. Ball joints can be some of the dirtiest components on the entire undercarriage, combined with mud and other road grit, and can be a major cause of trying to get a ball joint loose. For easier access, spray some metal cleaner on all the bolts to make it easier for the bolts to slide off.

Part Two: Removing the Old Ball Joint

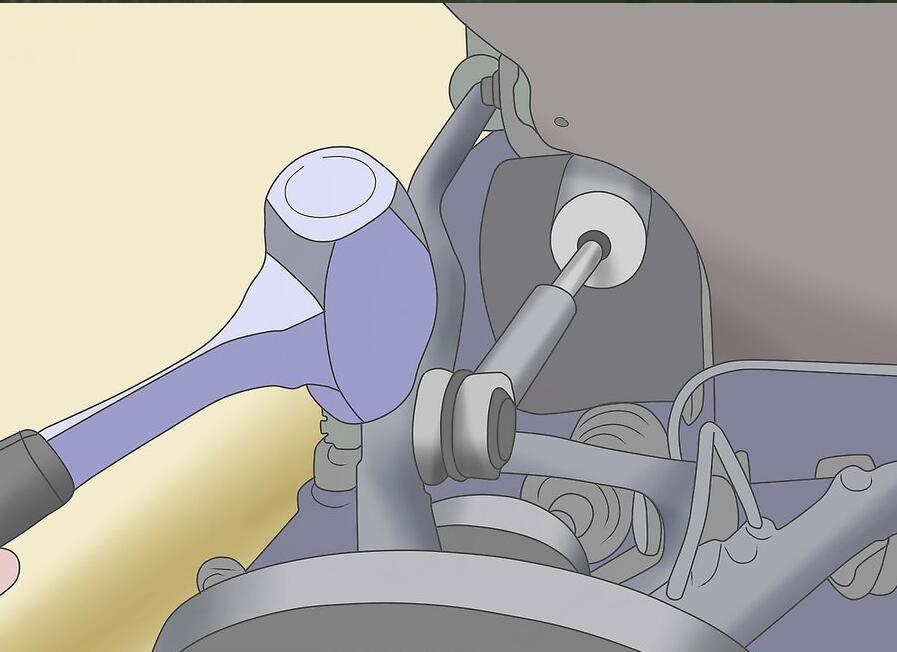

1. Pull the cotter pin and loosen the large castellated nut. The top should look like a crown or castle on the bottom. Leave the c-nut in place and keep it in a safe place with just a few turns.

2. Loosen the ball joint. The goal is to try and guide it through the hole in the top half of the knuckle. This can be a bit difficult as the very tight fit helps keep the ball joint in place and road grime builds up around the suspension so a hammer and a special tool called a "pickle fork" or a lever will most likely be required splitter for adequate leverage. Use a wrench to remove the largest nut on the joint, replace it with a new one, and drive the pickling fork between the control arm and knuckle. Or need to hammer it, and don't be afraid to get rough. By placing the c-nuts before hammering, you risk falling on the floor and damaging the parts and possibly your own feet

3. Remove the bolts and slide the control arm free. Loosen the bolts or drill out the rivets holding the ball joint in place and slide the ball joint off. If the car suspension uses press-fit ball joints, the lower control arm needs to be removed and the assembly brought to a mechanical unit with a hydraulic press that can press the old ball joint and the new ball joint in.

Part Three: Installing the New Connector

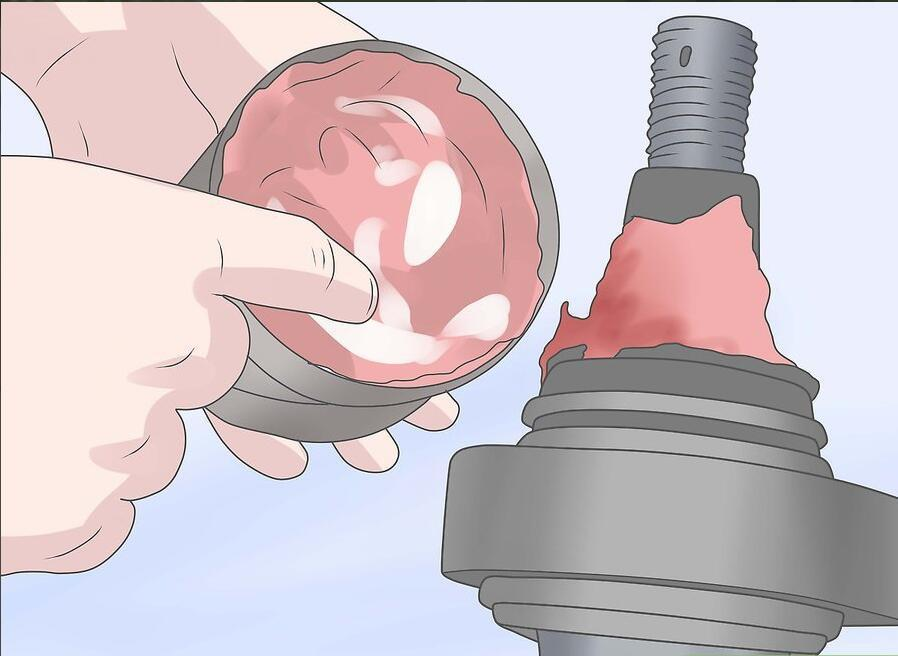

1. Guide the new joint through the knuckle hole. Slide the new rubber boot over the stud of the ball joint and guide the new ball joint up through the knuckle hole and from there.

2. Use the included hardware to secure the connector in place. It is generally not recommended to re-use old bolts or rubber boots that cover old ball joints, and if the ball joint is worn, it may corrode excessively.

3. Tighten the bolts to the proper specification. Use a torque wrench to tighten the bolts and c-nuts to the specified level; Generally, the gauge is about 44 pounds per foot for screws and about 80 pounds per foot for other bolts. However, be sure to follow the exact figures in your car's owner's manual.

4. Screw in the new grease fitting and pump the grease into the assembly. If the brakes or wheels were removed, reinstall them and lower the vehicle down to test the action. Bleed the brakes if necessary. You can take this opportunity to take care of other things that need to be taken care of together.

Jinjiang Huibang Zhongtian Machinery Co., Ltd. was established in 1987. It is a modern comprehensive manufacturer integrating R&D, production and sales of various types of vehicle chassis parts. Strong technical force. In line with the tenet of "Quality First, Reputation First, Customer First", we will continue to advance towards the specialization of high, refined, professional and special products, and serve the vast number of domestic and foreign customers wholeheartedly!

Post time: Apr-23-2023